Bga Solder Joint Crack Error Message

SMT - Intermittent BGA Test Problems • 1. CIRCUITNET December 26, 2014 Authored by: Circuitnet Intermittent BGA Test Problems Expert's Panel Responses • 1 SMT–IntermittentBGATestProblems INTERMITTENT BGA TEST PROBLEMS We're having problems with some BGA devices after SMT assembly. During testing the BGA devices are failing, however if we press lightly on the top of the problem BGA device during testing, the board passes. What is likely to be the cause? Is it more likely to be solder joint failure, or something internal within the BGA package?

Experts Comments This sounds like a typical 'head-in-pillow' (or 'ball-in-socket') defect that is a common issue with BGAs. In this case, the joint is not really metallurgically formed, but the two metal surfaces (the solder and the BGA ball) are mechanically touching each other. The amount of contact between the ball and the solder can vary with the temperature, or with pressure put onto the part (as you indicated in your question).

This is almost certainly not an internal issue with the component itself; it is a soldering defect at the interface between the ball and the solder. There have been a lot of studies conducted and technical papers written on prevention of head-in- pillow defects. One common cause is the component or board warping just enough that the ball loses contact with the solder paste just before the paste begins to reflow.

رسالة تحذيرية فى اجهزة اللاب توب BGA solder joint crack error message. كتب بواسطة سامح. Abstract: In this paper the influence of the temperature cycle time history profile on the fatigue life of ball grid array (BGA) solder joints is studied. Temperature time history in a Pentium processor laptop computer was measured for a three-month period by means of thermocouples placed inside the computer.

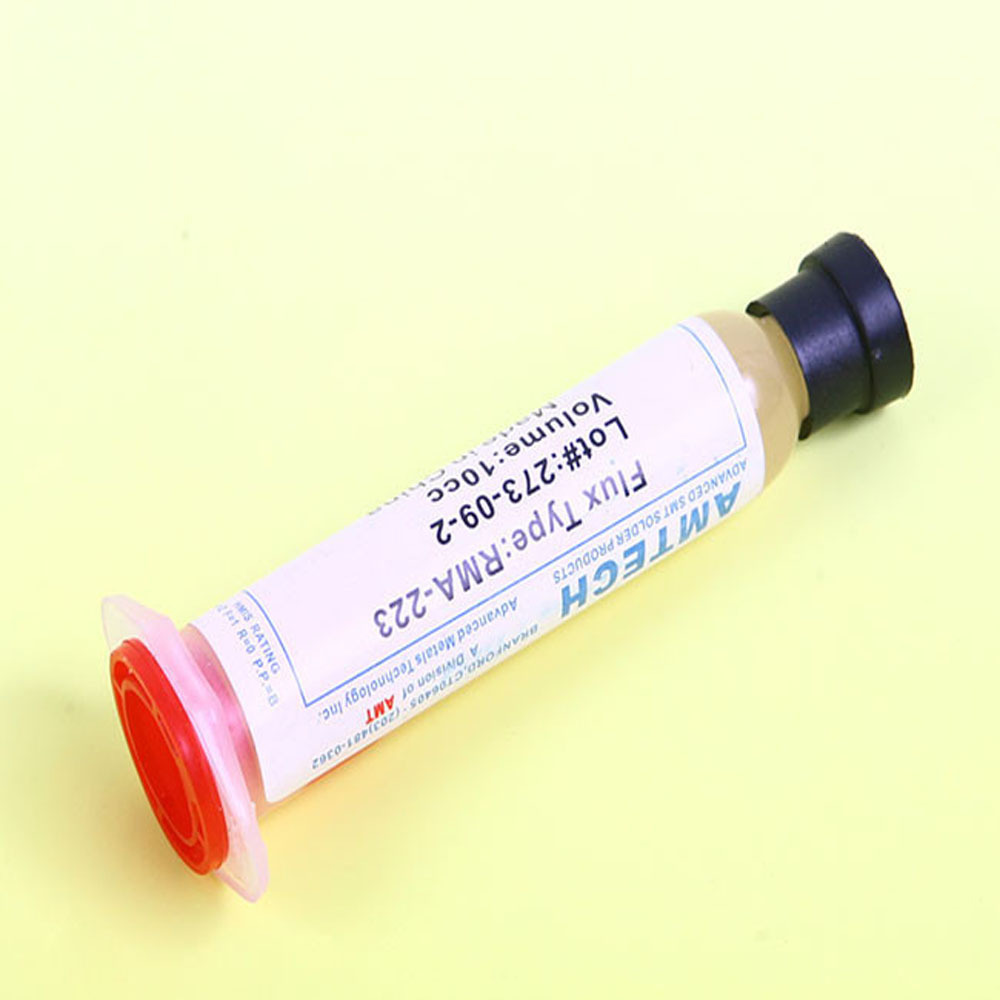

Another cause is that the reflow profile drives a Delta T across the component that can create some 'tilting' of the component, again just enough to let the ball lose contact with the paste just as the board reaches the liquidus temperature. This is often a complicated defect resolution, so I would suggest carefully studying the defect location(s) -- are the defects always occurring on the same parts, same locations on the same parts? Download Game Psp Iso Cso Highly Compressed. Is it directional -- if you turn the board 180 degrees heading into the oven, does the amount of locations of the defects change? I would also suggest to contact your solder paste supplier to see if they have any tips to help with this. If you contact me directly, I can provide a few papers to help get the process started for you.