Aqua-air V100 Manual

HydroPro tanks provide years of dependable water system storage and delivery service! The efficient design reduces pump on/off cycles, resulting in longer motor and switch life, and reduced power costs.

Valiant Hearts The Great War Soundtrack Download there. Welcome to the Water Systems division of A. Smith Where innovation has a name. V100 V350 V140 V80EX Stand Model with Base Extension V60MP V45MP Mounted Pump Models MODEL Maximum Working Pressure: 125 psi (except mounted pump models, 100 psi). Submersible Well Pumps from Aqua Science. Goulds V100, 32 Gallon, HydroPro Pressure Tank. The air pressure in the tank should be set to 38 PSI. Submersible Well Pumps from Aqua Science. Goulds V100, 32 Gallon, HydroPro Pressure Tank. The air pressure in the tank should be set to 38 PSI.

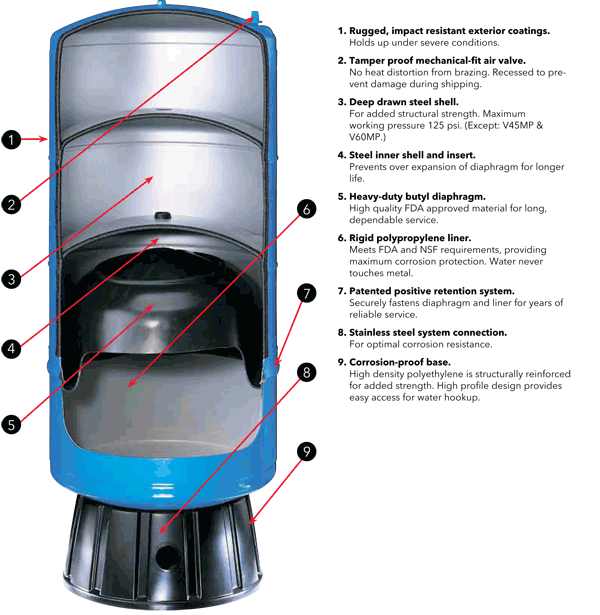

Each tank is factory tested and 100% air and water tight. FEATURES • Deep Drawn Steel Shells: Provide maximum material strength.

• Inner Shell: Prevents diaphragm from over-expanding. • Heavy Duty Diaphragm: Made of finest quality butyl rubber. Separates air and water, maintains air charge. • Interior Tank Lining: Features a durable polypropylene liner. Meets FDA requirements.

• Maximum Working Pressure: 125 psi • Temperature Rating: Maximum 120° F • Stainless Steel System Connection: On all models. • Appliance Appearance Exterior Finish: Blue color, high durability exterior finish of tough, powder coat over a zinc phosphate surface treatment. Cantonese Audio Bible Old Testament Download Free. Tanks are designed for installation indoors or where they are protected from rain, irrigation over-spray, salt air and other corrosive environments. Always protect tanks from freezing. • Heavy Duty Base: Made of high density polypropylene.

• Pre-charge: All tanks charged to 38 PSI. Since its inception in 1964, the pre-pressurized potable water tank has assumed various designs and has proven useful in a wide variety of open-system applications.

Originally used in well installations, this technology gained widespread acceptance and was soon applied in a variety of applications requiring pressurized water storage. With this flexibility, however, can come confusion as to installation scenarios and related sizing. Below, we 'll take a look at proper use and related sizing techniques in such applications as pump cycle control, volume maintenance, and water treatment systems. Common to the below examples is the fact that it is necessary to determine both the amount of tank storage needed and the pressures necessary to obtain that storage. Simply stated: All sizings use the same principle with different values. Referred to as Boyle's Law of Ideal Gases, this principle will be used to determine how much water is stored in tank at a given pressure.

This multiplier will be referred to as the Acceptance Factor. Keep this equation in mind as a foundation to size any pre-pressurized tank: Pump Systems It is common knowledge in the water systems industry that cycling a pump motor rapidly will often lead to failure. To prevent this, most pump manufacturers normally recommend a minimum pump runtime of 2 minutes. In order to achieve the runtime, the pre-pressurized tank must store a given volume of water between pump cycles.